HZ SCALLOPED BELTS (FOR MOTOR VEHICLES)

APPLICATION

– Automotive industry:

the gas distribution mechanism of the vehicle internal combustion engine.

Globelt HZ is a specially designed belt for motor vehicle shaft gas-distribution drives.

ADVANTAGES

– reliable operation;

– maximum performance and durability;

– power transmission without slipping;

– high wear-resistance;

– resistance to temperature impact within the range of -30 °С to +120 °С;

– antistatic treatment (ISO 1813).

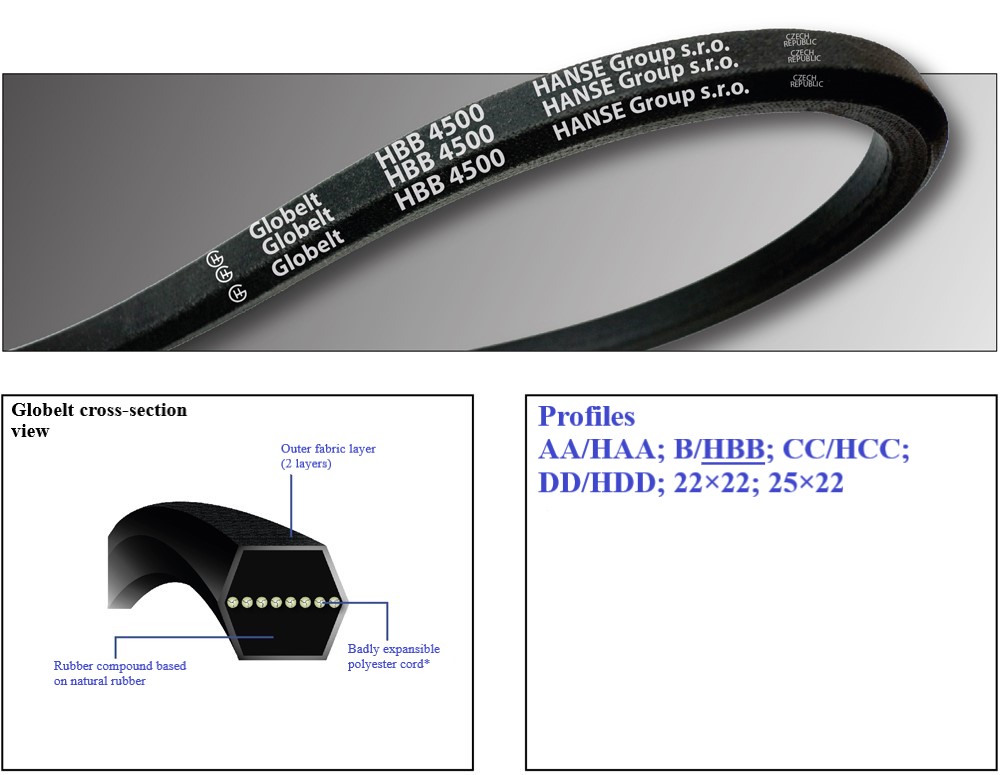

Two-sided V-BELTS

APPLICATION

– Agriculture:

combine harvesters, hay mowers;

– Mechanical engineering:

special drives with variable rotation direction;

– Municipal services:

road sweepers;

– Gardening:

self-propelled lawn mowers.

ADVANTAGES

– reliable operation;

– elasticity;

– optimal driving properties;

– minimum stretch;

– wear-resistant two-layer outer fabric;

– high power transmission;

– resistance to temperature impact within the range of -50 °С to +70 °С;

– antistatic treatment (ISO 1813).

*Badly expansible polyester cord "High Tenacity Soft Cord"

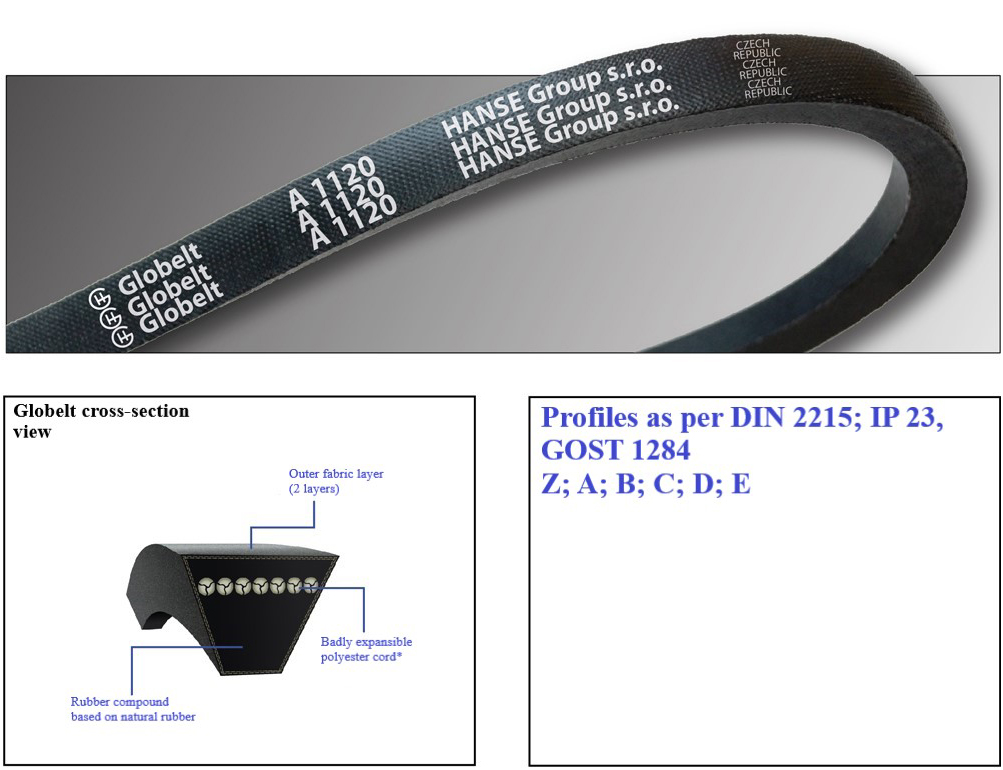

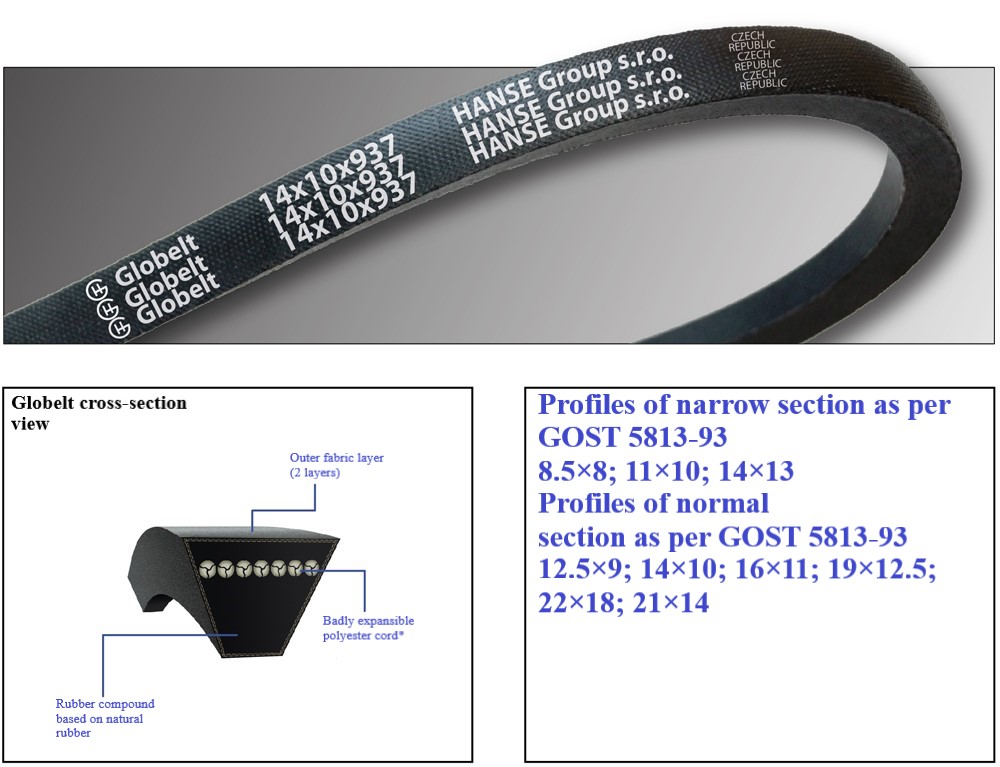

Wrapped V-BELTS of normal cross-section

APPLICATION

– Mechanical engineering:

machine tools and equipment, crushers and presses;

– Agriculture:

combine harvesters, grinders, presses;

– Construction:

agitators, equipment drives;

– Gardening:

lawn mowers, mechanical hoes.

ADVANTAGES

– reliable operation;

– long operation life;

– uniform power transmission;

– wear-resistant two-layer outer fabric;

– resistance to temperature impact within the range of -50 °С to +70 °С;

– antistatic treatment (ISO 1813).

*Badly expansible polyester cord "High Tenacity Soft Cord"

CVT BELTS with open side faces and shaped teeth

APPLICATION

– Agriculture:

combine harvesters, thresher drives;

– Mechanical engineering:

lathes, adjustable pulley drives, special drives;

– Light industry:

textile winding machines;

– Printing industry:

printing machines, multi-color offset printing machines;

– Machines and mechanisms with infinitely variable speeds:

snowmobiles, ATVs, scooters, mopeds, self-propelled lawn mowers.

ADVANTAGES

– reliable operation;

– high transmission power;

– enforced transverse rigidity;

– excellent elasticity in the movement direction;

– smooth running at all speeds;

– slip resistance;

– good adjusting properties;

– resistance to temperature impact within the range of -30 °С to +60 °С;

– antistatic treatment (ISO 1813).

**Two-sided CVT belts are available on request (HSP series)

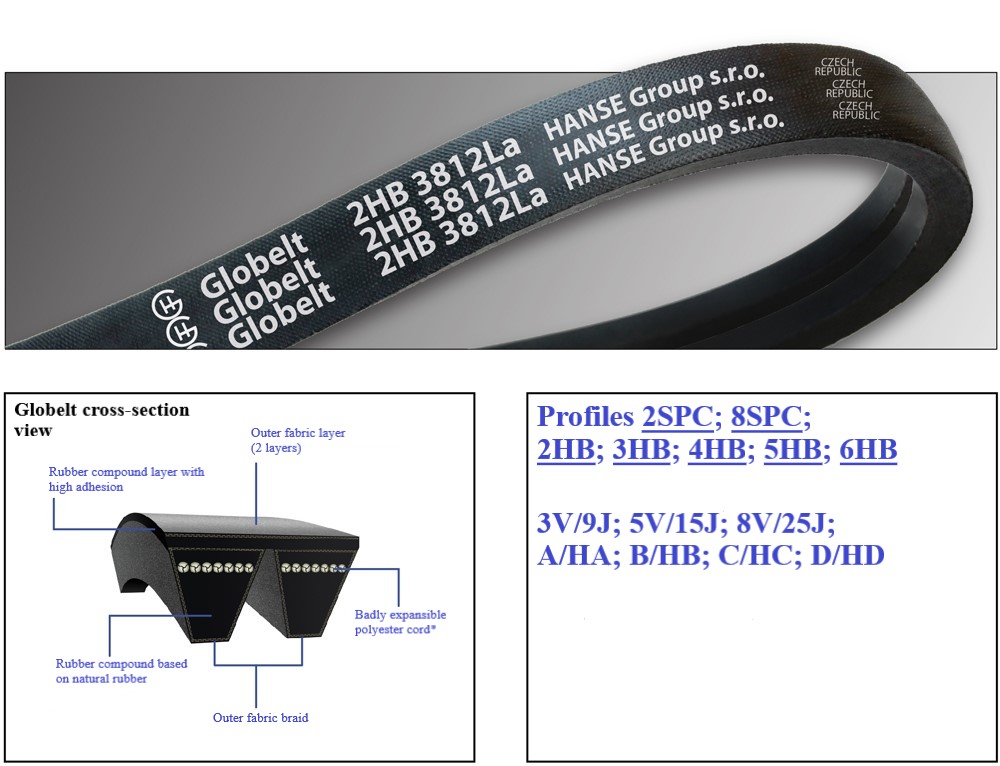

MULTILOOP BELTS

APPLICATION

– Agriculture:

combine harvesters, conveyors, and other agricultural machinery;

– Mechanical engineering:

plastic processing machines, agitators;

– Paper making industry:

hydraulic pulpers;

– Woodwork and timber industry:

sawmills;

– Quarries:

stone crushing plants, crushers, and screens;

– Road construction:

soil compacting machines and mechanisms.

ADVANTAGES

– reliable operation;

– maximum performance and durability;

– good elasticity;

– high tensile strength and length stability;

– low vibration;

– wear-resistant double outer fabric;

– high resistance to shock impact;

– resistance to temperature impact within the range of -40 °С to +80 °С;

– antistatic treatment (ISO 1813).

*Badly expansible polyester cord "High Tenacity Soft Cord"

**Use of polychloroprene rubber on request

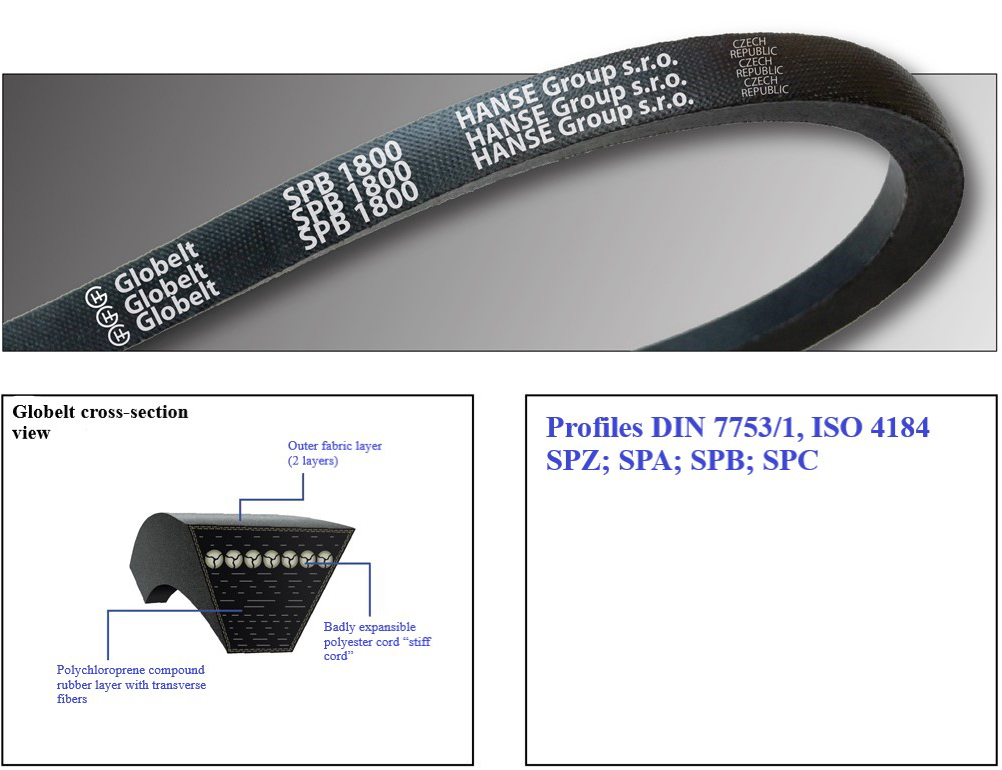

Wrapped V-BELTS of narrow cross-section

APPLICATION

Reinforced wrapped V-belts Globelt SPZ; SPA; SPB; SPC are ideal for industrial use. Their field of application is not limited. They are used to transmit high power under high loads in:

– Mechanical engineering;

– Road construction;

– Woodwork and timber industry;

– Agriculture;

– Mining industry;

– Oil and gas industry.

ADVANTAGES

– reliable operation when transmitting high power;

– optimal tension throughout the entire operation life;

– due to using the “stiff cord”, the service life is increased by 50%, the efficiency is increased by 35%;

– wear-resistant two-layer outer fabric coating with special impregnation treatment;

– high resistance to shock impact;

– resistance to temperature impact within the range of -50 °С to +70 °С;

– antistatic treatment (ISO 1813).

V-BELTS with open side faces and shaped teeth

APPLICATION

– Automotive industry:

electric generators, water pumps, fans, air conditioners, and other attached equipment;

– Mechanical engineering:

machine tools and equipment, fans, pumps, mills, special drives;

– Road construction:

black-top pavers;

– Woodwork and timber industry:

high-power sawmills;

– Agriculture;

– Quarries:

machines and mechanisms;

– Mining industry:

machines and mechanisms.

ADVANTAGES

– increased reliable operation when transmitting high power;

– extended operation life;

– wear-resistant two-layer outer fabric layer with special impregnation treatment;

– resistance to temperature impact within the range of -50 °С to +70 °С;

– antistatic treatment (ISO 1813);

– stable length.

POLY-V-BELTS (EPDM)

APPLICATION

– Automotive industry:

electric generators, water pumps, fans, air conditioners and other attached equipment;

– Mechanical engineering:

machine tools and equipment;

– Light industry:

textile machines;

– Paper making industry:

machine tools and equipment;

– Household appliances and tools.

ADVANTAGES

– high gear ratio;

– high power transmission;

– minimal slippage;

– ability to operate on pulleys of smaller diameters;

– increased abrasion resistance;

– resistance to temperature impact within the range of -45 °С to +130 °С;

– antistatic treatment (ISO 1813);

– low noise and vibration resistance.

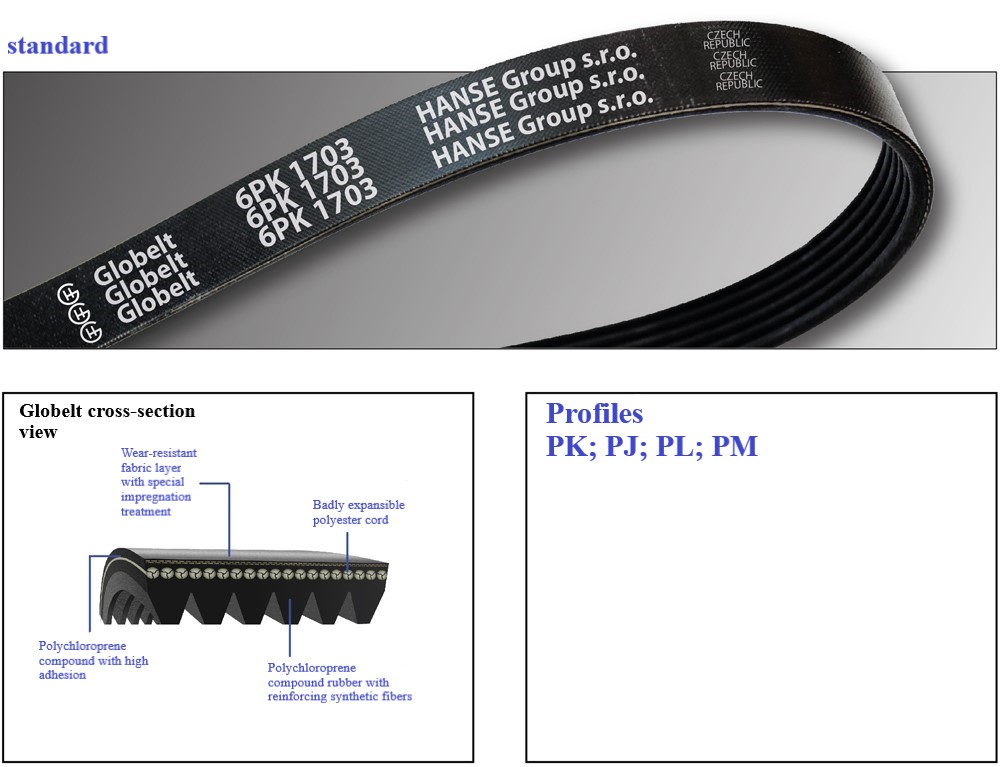

POLY-V-BELTS (Standard)

APPLICATION

– Automotive industry:

electric generators, water pumps, fans, air conditioners, and other attached equipment;

– Mechanical engineering:

machine tools and equipment;

– Light industry:

textile machines;

– Paper making industry:

machine tools and equipment;

– Household appliances and tools.

ADVANTAGES

– high gear ratio;

– high power transmission;

– minimal slippage;

– resistance to temperature impact within the range of -30 °С to +80 °С;

– antistatic treatment (ISO 1813);

– low noise and vibration resistance.

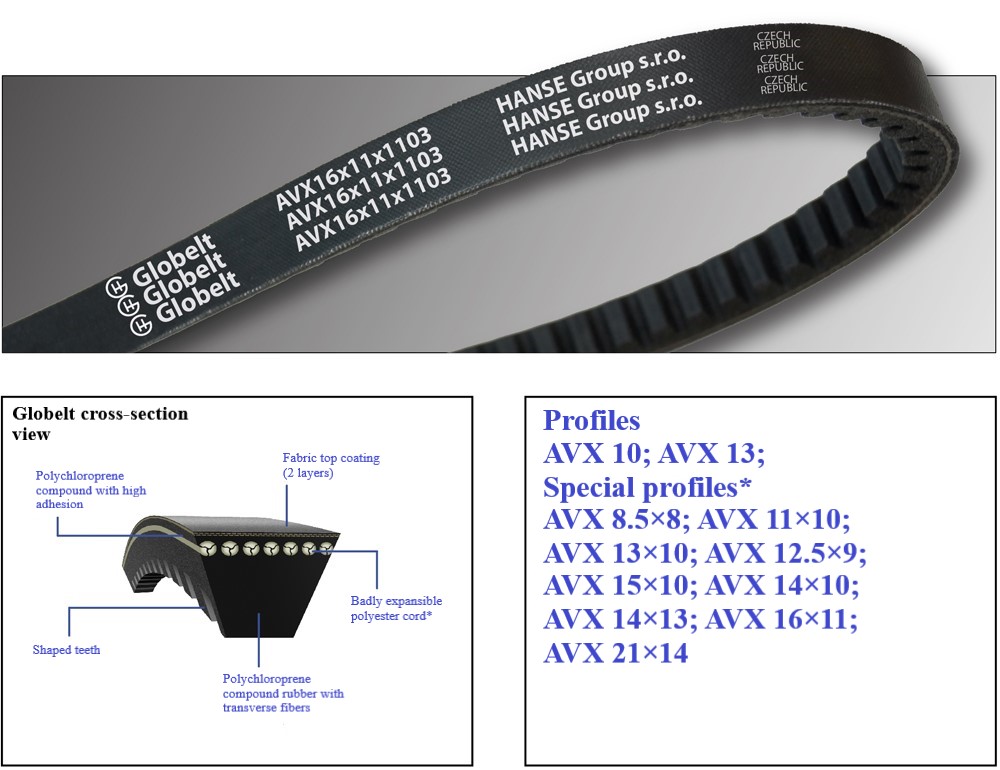

V-BELTS (FOR MOTOR VEHICLES)

with open side faces and shaped teeth

APPLICATION

– Automotive industry:

electric generators, water pumps, fans, air conditioners and other attached equipment;

– Mechanical engineering:

machine tools and equipment, fans, pumps, mills, special drives;

– Road construction:

black-top pavers;

– Woodwork and timber industry:

high-power sawmills;

– Agriculture;

– Quarries:

machines and mechanisms;

– Mining industry:

machines and mechanisms.

ADVANTAGES

– reliable operation;

– long operation life;

– optimal driving properties;

– high performance;

– smooth, silent operation;

– minimum stretch;

– resistance to temperature impact within the range of -50 °С to +70 °С;

– antistatic treatment (ISO 1813);

– ideal for vehicle engines of various makes and models.

*Badly expansible polyester cord "High Tenacity Soft Cord"

Fan V-BELTS (FOR MOTOR VEHICLES)

APPLICATION

– Automotive industry:

electric generators, water pumps, fans, air conditioners, and other attached equipment;

– Mechanical engineering:

machine tools and equipment, fans, pumps, mills, special drives;

– Road construction:

black-top pavers;

– Woodwork and timber industry:

high-power sawmills;

– Agriculture;

– Quarries:

machines and mechanisms;

– Mining industry:

machines and mechanisms.

ADVANTAGES

– reliable operation;

– long operation life;

– optimal driving properties;

– minimum stretch;

– wear-resistant two-layer outer fabric;

– resistance to temperature impact within the range of -50 °С to +70 °С;

– antistatic treatment (ISO 1813);

– cost efficiency when used in commercial vehicles engines of various makes and models.

*Badly expansible polyester cord "High Tenacity Soft Cord"

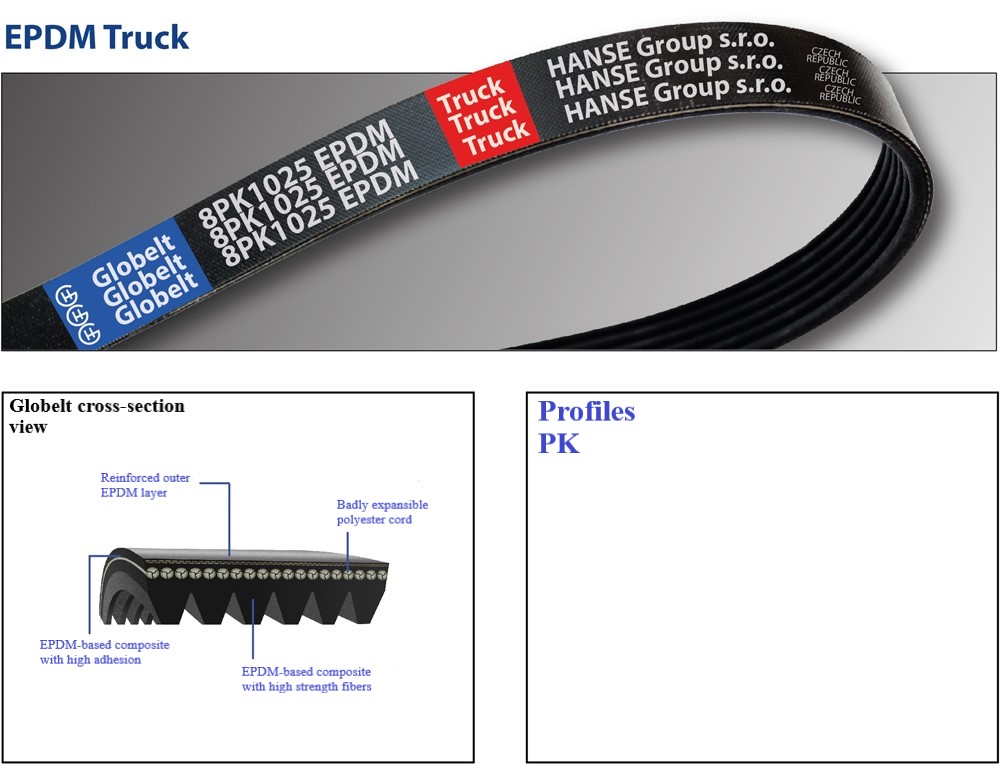

POLY-V-BELTS (EPDM Truck)

APPLICATION

– Automotive industry:

electric generators, water pumps, fans, air conditioners, and other attached equipment; in commercial vehicles and buses.

ADVANTAGES

– high gear ratio;

– high power transmission;

– no slippage;

– ability to operate on pulleys of smaller diameters;

– increased abrasion resistance;

– increased ozone resistance;

– significantly increased durability;

– resistance to temperature impact within the range of -45 °С to +130 °С;

– antistatic treatment (ISO 1813);

– low noise and vibration resistance.

QUALITY

Globelt-branded Belts for high power transmission may include up to 12 different components. Their service life and reliability are based on a high technological standard of well-proven and state-of-the-art designs. Due to special manufacturing methods, our sophisticated production processes guarantee high-quality drive belts.

The quality of Globelt products, such as V-belts and poly-V-belts, is appreciated by many well-known original equipment manufacturers and companies engaged in maintenance, repair, and operation worldwide.

Hanse Group s.r.o. is aware of our responsibility for human safety and improving the community’s living standards. As a matter of course, we adhere to all requirements and numerous environmental standards for manufacture of our high-performance products. Caring for the people’s safety and the environment is a tradition of HANSE Group.

HANSE Group’s Quality Policy:

Ask your questions about products and quality by phone:

+420 77 475 77 55

FOR PARTNERS

We value our partners and, therefore, we offer our cooperation to all trading and manufacturing companies to maintain and develop high competencies, reliability, and high quality of service.

By choosing HANSE Group s.r.o., you will get:

Product manufacture according to your exclusive orders:

Ask your questions about exclusive orders by phone:

+420 77 475 77 55

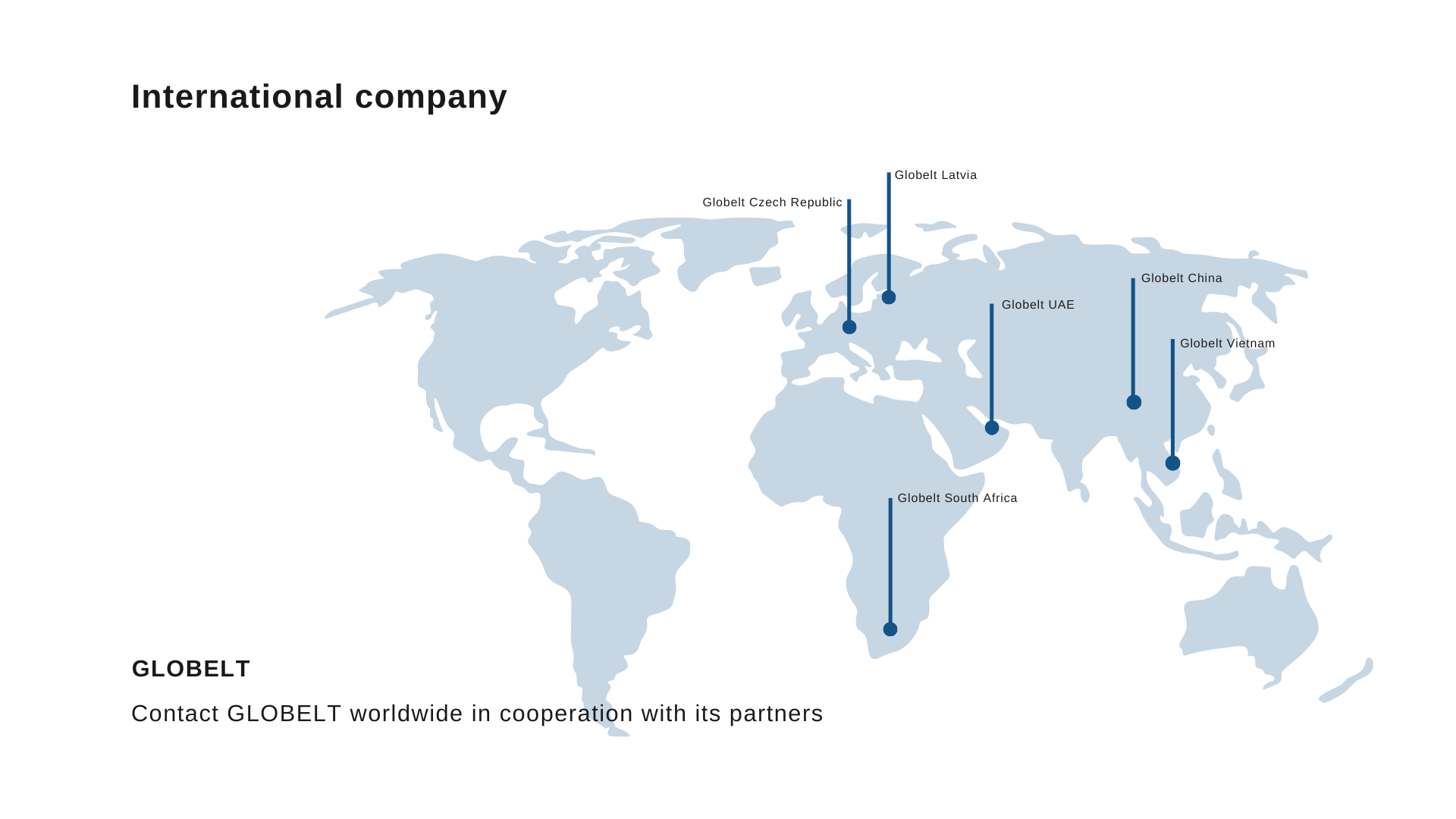

A division of the Hanse Group, GLOBELT is one of the leaders in innovation and technology in the production of drive belts for agricultural machinery, trucks and cars, tractors, road construction and special equipment, industrial companies.

Reliable quality and long-term cooperation are our priority, which is why we develop solutions for our customers and partners all over the world. We have extensive experience in materials and processes.

At our production sites in various countries, we strictly adhere to quality standards and production techniques under the supervision of leading Hanse Group specialists. We guarantee high quality standards of GLOBELT products manufactured in our factories and promptly deliver GLOBELT belts anywhere in the world in the shortest possible time. Thus, we are always there when you need us.

The contents of this publication are not legally binding and are provided as information only. The trademarks appearing in this publication are the property of Hanse Group s.r.o. and/or its subsidiaries.

Copyright © 2022 Hanse Group s.r.o. All rights reserved.

HANSE Group s.r.o.

Address: Zrzavého 1705/4a, 163 00 Praha 6, Czech Republic

Telephone: + 420 77 475 77 55

Commercial office:

«Geopart AD» s.r.o.

Address: Barovska 856/14,155 41 Praha 5, Czech Republic

E-mail: info@geopartad.cz

Telephone: +420 77 798 34 77

Contact person: I.Mazur